HOW IT WORKS

The UNI-VEE fixture has the potential to revolutionize your workflow, find out how below.

Select your Jaws

Need custom Jaws? Machine jaw blanks (sold separately) onsite using your UNI-VEE as the fixture for ultimate accuracy.

Set up your UNI-VEE

Choose the attachment method to your machine tool element.

Lock in the Part

You may now may now commence machining with the utmost precision and safety.

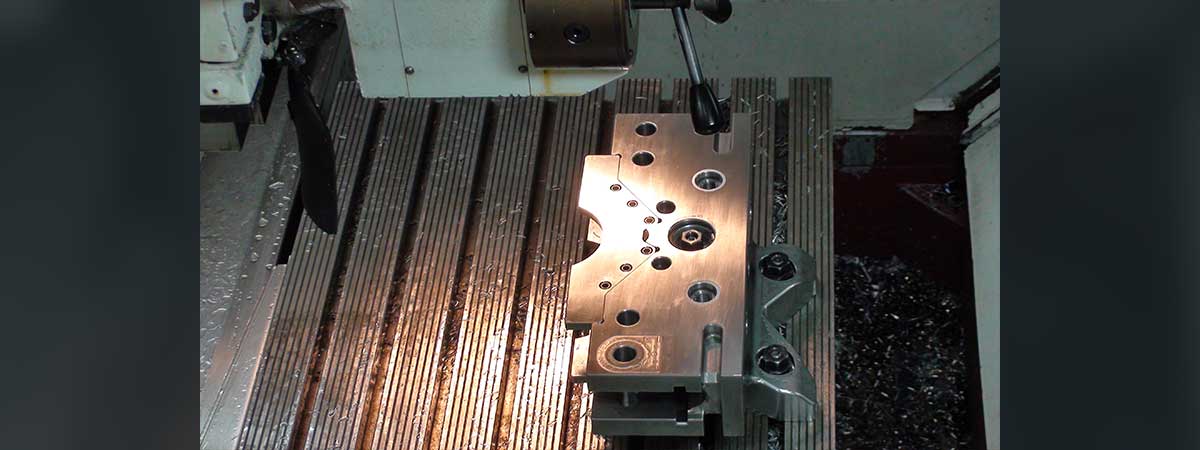

The UNI-VEE in Action

Explore the slideshow below to see an example of custom Jaw production – vertical spindle example

How it Works

The UNI-VEE is configured with a geometrically correct rectangular Main Body with identical locating features on 3 faces, supporting indexing in 90 degree increments about its horizontal centerline. This allows quick, repeatable horizontal/vertical Workpiece positioning when used with a mounting plate and facilitates laying down the UNI-VEE for the contouring of custom jaws, eliminating the need for a special fixture and increasing the accuracy of Your shop-built jaws. Additionally, it allows the ability to quickly and accurately rotate the fixture 180 degrees about its vertical axis in any of these configurations, increasing Workpiece access. With no protrusions on its front, back or bottom, UNI-VEE can lay flat on a table or surface plate, or even be installed directly into Your milling vise.

Quick, Simple, Clean

The UNI-VEE design results in a diverse, new and useful combination of benefits including:

- The establishment an absolute datum that doesn’t move and can be located prior to installing the workpiece.

- The ability to find the exact center of fixture rotation.

- Accurate set-up of the workpiece.

- Elimination of the need to dial in a part in many instances.

- Ease of inspection.

- Holding length tolerances.

- Machining of some workpieces that are otherwise too large.

- The ability to accurately align blind, opposing features.

- Large range of capacity.

- Exchangeable, configurable Jaws that can be made as needed on site.

- Smooth, positive operation.

- No workpiece rotation during clamp/unclamp operation.

- Built in Indexing capability.

- Integration compatibility.

- Supports transfer between machines without releasing workpiece.

- Progressively increasing leverage offering powerful clamping force.

- Workpiece clamping forces are internally resolved.

- Adjustable final tension.

- Repeatable clamping tension.

- Instant lock/unlock action.

- Replaceable wear parts.

- Uses standard, commonly available chain.

- Clamping mechanism can be operated from two sides.

- Flush faces for simple mounting.

- Auxiliary clamping slots wrap around end for greater access.

- Fits in a standard mill vise.

- Can be handled without a hoist.

- Sealed mechanism helps prevent entry of foreign materials while retaining lubricant.

- Minimal coolant pooling.

- Quick, simple cleanup.